People usually start with one simple question. How much is a custom metal gate going to cost? And the frustrating answer is always the same. It depends.

That is not a dodge. It is just how these projects work. A gate is not something pulled off a shelf. Every driveway, entrance, and property layout brings its own problems to solve. Hand Crafted Metalworks deals with this daily, and the price changes for reasons most buyers do not think about at first.

This is a breakdown of what actually drives the cost, without fluff and without pretending there is a single number that fits everyone.

Design is usually where costs either stay reasonable or climb fast. A simple, straight bar gate with clean lines is quicker to build and easier to install. Once curves, patterns, or decorative sections come into play, the work increases.

Metal does not bend itself. Every curve needs shaping. Every cut needs precision. If the design includes custom panels, layered pieces, or anything decorative, it takes time. Time equals labor. Labor equals cost.

Thickness matters too. Thicker metal gives strength and weight, but it also takes longer to fabricate and install. Thin material might look fine at first, but it can warp or flex over time, especially on wider gates.

Finishing is another big piece. A basic painted finish costs less upfront. Powder coating or weather-resistant finishes cost more, but they protect the gate longer. Skipping this part to save money often backfires later. All of this feeds directly into the final custom metal gate cost, even if the gate looks simple at a glance.

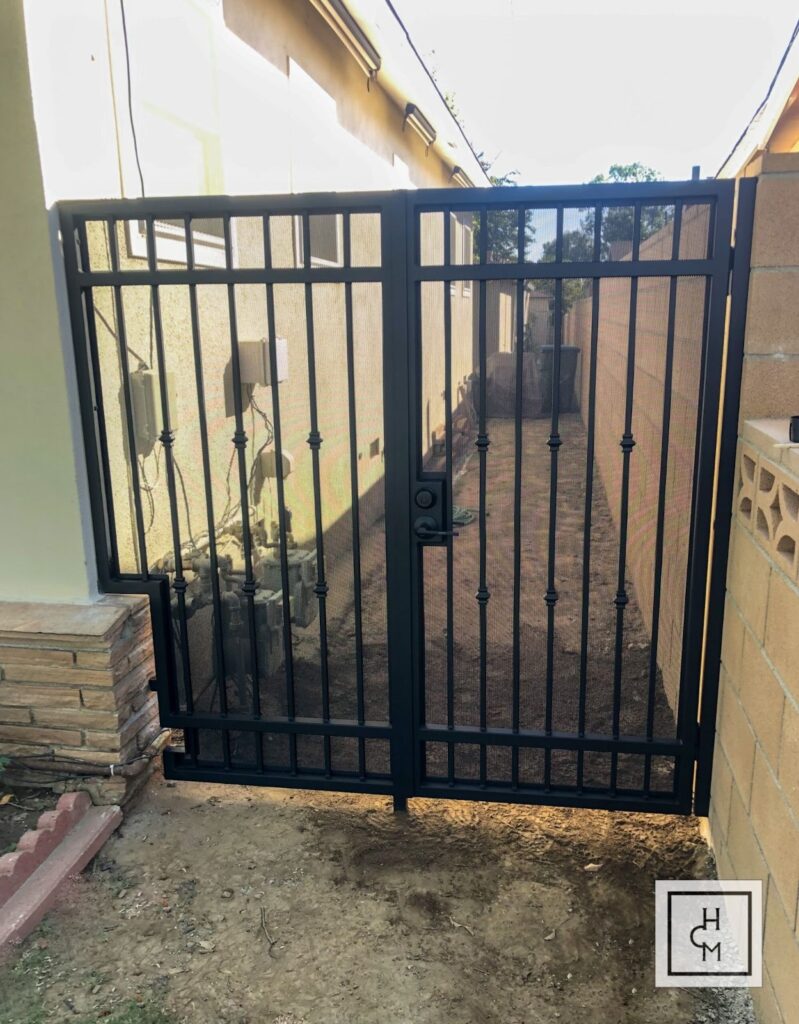

Alt Tag: Custom metal gate

Gate size sounds obvious, but it catches people off guard. A wider or taller gate is not just more metal. It needs more support to keep it from sagging or shifting.

A small pedestrian gate is light and easy to mount. A wide driveway gate needs reinforced framing, stronger hinges, and heavier posts. Double swing gates and sliding gates bring their own structural needs.

Weight changes everything. Heavier gates need better hardware and sometimes different installation methods. If automation is planned, the motor has to match the weight, which adds to the total. Big gates are not just scaled-up versions of small ones. They are different builds entirely.

Some gates stand alone. Others are part of a bigger setup that includes fencing, railings, walls, or entry features. This is where architectural metalwork services come in.

When a gate needs to match surrounding metalwork, measurements must be exact. Posts may be custom-built. Panels might need to line up with existing structures. Small errors show immediately, so extra planning is required.

This kind of work also involves coordination. Fabrication has to match site conditions, not just drawings. Sometimes adjustments happen on-site because real spaces are never perfectly square. Architectural metalwork services add value, but they also add steps. Those steps affect pricing whether people see them or not.

Ready to price out your custom metal gate?

Two identical gates can cost different amounts to install. The reason is the site.

Ground conditions matter. Soft soil may need deeper footings. Sloped driveways may need leveling; remember that it adds time and material. Tight access areas slow down equipment and labor.

Removing an old gate also counts. If posts are buried deep or set in heavy concrete, removal is work on its own. Existing walls or pillars may need adjustment to support the new gate. None of this is guesswork. Experienced installers factor it in early to avoid problems later.

Manual gates are straightforward. Automation changes the entire project. Motors, control boards, safety sensors, remotes, and access systems all add cost. Heavier gates require stronger motors. Stronger motors cost more and need a proper electrical setup.

Hardware quality matters more than people think. Cheap hinges wear out. Low-grade rollers cause alignment problems. Replacing these later costs more than installing good hardware from the start.

Power access also affects price. Running electrical lines or setting up solar systems depends on distance and layout. Once automation is involved, details multiply quickly.

Steel, aluminum, and wrought iron all behave differently. Steel is strong and versatile, but it needs proper protection from rust. Aluminum is lighter and resists corrosion, but it can cost more initially. Wrought iron has a classic look but takes skilled hands to fabricate correctly.

Material choice affects how the gate ages. A cheaper option upfront may need more maintenance or repairs later. This is where guidance matters. Hand Crafted Metalworks often helps clients balance look, durability, and budget so the gate still performs years down the line.

Alt tag: custom metal entry gates

Trying to cut corners on a gate usually shows sooner than expected. Sagging, rust spots, and hardware issues do not take long to appear.

Spending a bit more on proper fabrication, solid finishes, and quality components usually saves money long term. Repairs are not cheap. Neither is replacement. A well-built gate should work quietly and look the same years later. That is the real.

There is no single formula. Pricing comes from combining design complexity, material choice, size, installation conditions, and optional features.

Accurate quotes come after proper measurements and honest conversations. Rushing the process creates problems later.

A custom gate should feel like it belongs on the property. When that happens, the cost usually feels justified.

Not sure where to start with design or materials?

How long does a custom metal gate take to complete?

For Hand Crafted Metalworks, the majority of projects associated with custom metal gate cost factors can be completed in a few weeks from final design approval to installation. More intricate design details or larger gates may stretch the duration slightly.

Is it possible to cut costs without sacrificing excellence?

Yes. Keeping the design simpler and choosing standard finishes instead of specialty options helps control pricing without cutting corners on strength or durability.

Are custom metal gates difficult to maintain?

Only light upkeep is needed. Simple maintenance, including regular cleaning and periodic hardware or finish inspection are a good start, particularly for outdoor installations.

Does every gate need to be automated?

Not only if possible, dependent on the number of times it is used and personal preference, but best used for high traffic entrances.