Ordering a metal gate or fence sounds simple at first. You see a few photos online, pick a style, get a quote, and wait for installation. But once you get into it, the questions start stacking up. Materials, finishes, measurements, timelines, permits. Miss the wrong detail, and you end up with something that looks fine in photos but feels wrong every time you pull into your driveway.

At Hand Crafted Metalworks, most problems we see did not start at the shop. They started with unanswered questions. So before you place an order, here are the things worth asking. Some are practical. Some save money. Some just save you from frustration later.

Before anything else, ask yourself why you are going custom. This matters because it shapes every other decision.

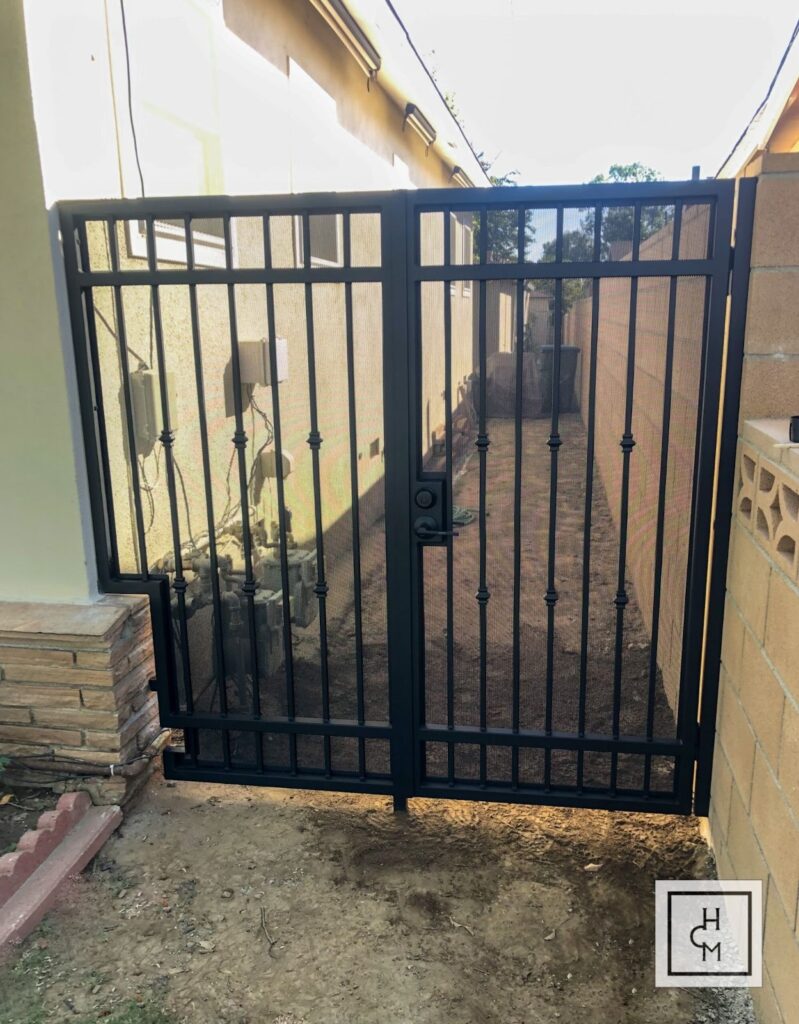

Custom metal gates and fences are usually chosen because standard sizes do not fit the property, the style needs to match an existing home, or durability is a priority. Custom also means more responsibility. You are not buying a boxed product. You are commissioning a build.

Ask the fabricator how custom the work really is. Are they adjusting a template or building from scratch? There is a big difference in cost, lead time, and flexibility.

Not all metal is created equal. Some shops will default to mild steel. Others recommend aluminum or wrought iron. Each has pros and drawbacks.

Ask what metal is being used and why it suits your location. Coastal areas need better corrosion resistance. High-traffic entrances need strength. Decorative courtyard gates might prioritize detail over weight.

This is where good Metalwork shows. A skilled shop will explain the tradeoffs instead of pushing whatever is cheapest to fabricate.

The finish is not just about looks. It is about lifespan.

Ask how the metal is treated before painting or coating. Is it sandblasted? Primed? Powder-coated? Hand-painted? Skipping steps saves time but costs you later.

Also, ask how the finish holds up over time. Will it fade? Chip? Rust at weld points? And what maintenance is expected? If the answer is vague, push for details.

A good finish should protect your investment for years, not just until the invoice is paid.

Ready to plan your custom gate or fence?

Get a Quote

Never assume measurements are your responsibility unless clearly stated.

Ask who comes out to measure and when. Gates in particular are unforgiving. A half-inch mistake can turn into a costly delay or a gate that never swings right.

Hand Crafted Metalworks always prefers to handle measurements on site. If a shop relies entirely on customer measurements, that is a risk worth thinking about.

A gate is something you use constantly. Ask about how it opens, closes, and locks.

Is it manual or automatic? Swing or slide? Inward or outward? What kind of latch or lock is included? Can it be upgraded later?

Also, ask how heavy it will be. Heavier is not always better if hinges and posts are not designed to support it long term.

This is where custom metal gates and fences need practical thinking, not just good looks.

This question saves the most arguments later.

Ask what the quote includes, line by line. Fabrication, finishing, delivery, installation, hardware, posts, and footings. Are permits included? Electrical work for automatic gates?

If something is not listed, assume it is not included. Clear quotes protect both sides.

Some fabricators don’t handle their own installations. That’s not always a problem, but you should be aware.

Ask whose fault if something you are putting in doesn’t fit or work correctly. Are the shop and installer coordinated? Who warrants the installation?

Problems get solved more quickly when the same team does both fabricating and installing.

Custom work takes time. That is expected. What is not expected is silence.

Ask how long fabrication takes and what might delay it. Ask when the installation happens after fabrication is complete. Ask how updates are communicated.

A realistic timeline is better than a fast promise that slips.

Photos count, but details count more.

Ask for samples of similar projects, not just highlight pieces. Search out clean welds, uniform spacing, intact posts, and finishes that look good after install.

If you can, find out about previous clients or reviews. A Metalwork deck should not be shy to flex its muscles.

Custom does not mean unlimited changes without cost.

Ask when design changes are allowed and when they become expensive. Once fabrication starts, even small changes can mean starting over.

Clear communication early avoids disappointment later.

Metal lasts a long time. Problems usually show up early if they show up at all.

Ask what is covered under warranty. Finish issues? Hardware failure? Structural problems? And for how long?

Also, ask who to contact if something needs adjustment after installation. Gates settle. Hinges need tuning. That support matters.

A gate in a quiet residential street has different demands than one at a commercial entrance.

Ask if the design accounts for wind load, ground movement, traffic, or slope. A beautiful gate that drags on the ground every monsoon season is not a success.

This is where experience matters more than style.

Ordering custom metal gates and fences is not just a purchase. It is a small construction project. The more you ask upfront, the smoother it goes.

At Hand Crafted Metalworks, we encourage questions because they lead to better results. Good Metalwork is not rushed, not vague, and not guesswork. It is planning, skill, and follow-through.

If a fabricator welcomes your questions, you are probably in the right place. If they brush them off, that tells you something, too.

Have questions about design, durability, or installation?

1. How long do custom metal gates usually last?

With proper materials and finishing, they can last decades. Maintenance and environment play a big role.

2. Are custom designs much more expensive than standard ones?

Not always. Cost depends on complexity, material, and finish. Simple custom designs can be close in price to pre-made options.

3. Do metal gates require a lot of maintenance?

They need some care. Occasional cleaning and touch-ups help extend the finish and prevent corrosion.

4. Can existing posts or walls be reused?

Sometimes yes, sometimes no. It depends on their condition and whether they can handle the new gate’s weight and movement.